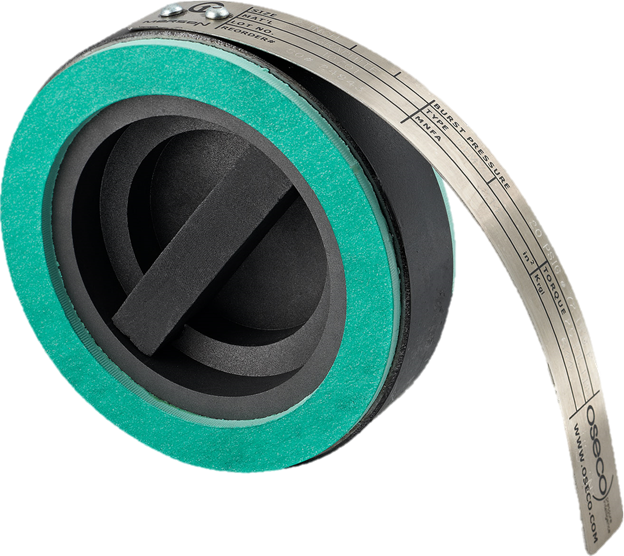

OsecoElfab’s GTM Rupture Disc

The GTM, or Graphite Monoblock, rupture disc is a simple, graphite pressure relief device that offers an economical solution for a wide range of applications. With sizes ranging from 1” to 24”, the GTM is ideal for applications that need an easy, inexpensive pressure safety device. The GTM does not require an external holder and is intended to install directly into an ANSI RF or FF flange joint. The GTM is designed for operation in applications where normal system pressures do not exceed 50% of the stamped burst pressure.

- The GTM is available in line sizes ranging from 1 inch diameter all the way up to 24 inches diameter.

- The GTM is available in burst pressures ranging from 0.5 psig all the way up to 400 psig.

- The GTM is available in burst temperatures ranging from cryogenic temperatures all the way up to 365+ degrees F.

- The GTM is only available in graphite materials of construction.

- The GTM works well in gas or vapor services, as well as liquid or two-phase services.

- The GTM is ASME UD stamped, with a Kr value of Krgl = 0.6, and when an optional vacuum support is added, the GTMV has a Kr value of Krgl = 6.44.

- The GTM has a 90% operating ratio, but only in static pressure services. This means the GTM operates reliably and with a long service life at pressures up to 90% of the marked burst pressure. Pressure excursions above this 90% operating ratio will shorten the lifespan of the GTM, as will repeated pressure swings or oscillations between 50% to 90% of marked burst pressure.

- The GTM is offered with a standard 0% Manufacturing Design Range (MDR), meaning there will never be any variation between what burst pressure you order, and what burst pressure is marked on the tag of the rupture disk.

- The GTM maintains or exceeds the ASME-specified burst tolerances of +/- 5% of marked burst pressure for burst pressures above 40 psig, or +/- 2 psig for burst pressures at or below 40 psig.

- The GTM is a graphite rupture disk, with potential for fragmentation. This means the GTM, and graphite rupture disks in general, cannot and should not be installed upstream from a pressure relief valve.

- The GTM requires a vacuum support in most applications that involve vacuum. The model name shifts to GTMV, the V for vacuum support.

- The GTM is designed to be installed directly into an ANSI flange joint with raised facings or flat facings. No holder is required to use the GTM rupture disk.

- The overall height of the GTM from line sizes 1 inch through 3 inch is only 5/8 inch tall. From line sizes 4 inch through 24 inch, the GTM is 7/8” tall.

- The GTM is a flat, graphite rupture disk, with a flat outlet side, and a milled, or machined inlet side. Process pressure is applied to the milled inlet side of the rupture disk. Increasing process pressure induces crack formation and propagation through the thinned, or milled portion of the disk. At the burst pressure, brittle fracture failure occurs, and the central, milled portion of the disk shatters, allowing process fluid to escape through the rupture disk.

- The GTM, like all flat, graphite rupture disks, does best in static pressure applications. The GTM handles pressure cyclic services fairly well, but reverse acting metal rupture disks are typically recommended for services with oscillating pressures.

- The GTM is designed, manufactured, and certified to ASME BPVC Section XIII requirements.

- The factory must be consulted for MNFA values for the GTM rupture disk.

- For a 1” GTM, the minimum burst pressure is 15 psig, and the maximum burst pressure is 400 psig.

- For a 1.5” GTM, the minimum burst pressure is 10 psig, and the maximum burst pressure is 300 psig.

- For a 2” GTM, the minimum burst pressure is 4 psig, and the maximum burst pressure is 250 psig.

- For a 3” GTM, the minimum burst pressure is 3 psig, and the maximum burst pressure is 200 psig.

- For a 4” GTM, the minimum burst pressure is 2 psig, and the maximum burst pressure is 150 psig.

- For a 6” GTM, the minimum burst pressure is 2 psig, and the maximum burst pressure is 100 psig.

- For an 8” GTM, the minimum burst pressure is 1 psig, and the maximum burst pressure is 100 psig.

- For a 10” GTM, the minimum burst pressure is 1 psig, and the maximum burst pressure is 100 psig.

- For a 12” GTM, the minimum burst pressure is 0.5 psig, and the maximum burst pressure is 100 psig.

- For a 14” GTM, the minimum burst pressure is 0.5 psig, and the maximum burst pressure is 75 psig.

- For a 16” GTM, the minimum burst pressure is 0.5 psig, and the maximum burst pressure is 75 psig.

- For a 18” GTM, the minimum burst pressure is 0.5 psig, and the maximum burst pressure is 50 psig.

- For a 20” GTM, the minimum burst pressure is 0.5 psig, and the maximum burst pressure is 50 psig.

- For a 24” GTM, the minimum burst pressure is 0.5 psig, and the maximum burst pressure is 25 psig.