OsecoElfab’s STD Rupture Disc

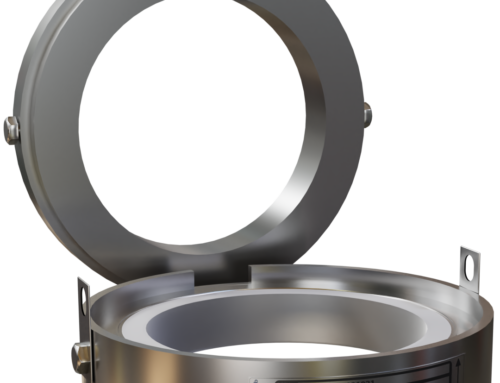

The STD, or Standard, rupture disc is a simple, forward acting pressure relief device that offers an economical solution for a wide range of applications. This solid metal, crowned, or pre-bulged, disc excels in gas or liquid applications. The STD is commonly used in high pressure, small diameter, applications to vent pressure to controlled areas or to the atmosphere. The STD is designed for operation in applications where normal system pressures do not exceed 70% of the stamped burst pressure. This will ensure excellent and long service life.

- The STD is available in line sizes ranging from 0.25 inch diameter all the way up to 24 inches diameter.

- The STD is available in burst pressures ranging from 145 psig all the way up to 50,000+ psig.

- The STD is available in burst temperatures ranging from cryogenic temperatures all the way up to 900 degrees F.

- The STD is available in all OE standard materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276). Other materials may be available or offered on request.

- The STD works well in gas or vapor services, as well as liquid or two-phase services. The STD works particularly well in sticky or fouling services.

- The Kr value for the STD, is Krgl = 0.88, however when a vacuum support is required, the Kr value for the STDV is Krgl = 1.98.

- The STD has a 70% operating ratio, meaning the STD operates reliably and with a long service life at pressures up to 70% of the marked burst pressure. Pressure excursions above this 70% operating ratio will shorten the lifespan of the STD.

- The STD is offered with a standard (-)10% Manufacturing Design Range (MDR), meaning the marked burst pressure could deviate from the ordered or specified burst pressure as much as 10% below the specified burst pressure. Reduced or shifted manufacturing range options are available on request.

- The STD maintains or exceeds the ASME-specified burst tolerances of +/- 5% of marked burst pressure for burst pressures above 40 psig, or +/- 2 psig for burst pressures at or below 40 psig.

- The STD is a non-scored metal rupture disk, with potential for fragmentation. This means the STD cannot and should not be installed upstream from a pressure relief valve.

- The STD requires a vacuum support in most applications that involve vacuum. The model name shifts to STDV, the V for vacuum support. The STD *can* handle vacuum service without a vacuum support, but only when the disk material is thick enough. This means that STD disks with low burst pressures cannot withstand full vacuum and should always use a vacuum support when exposed to any amount of vacuum.

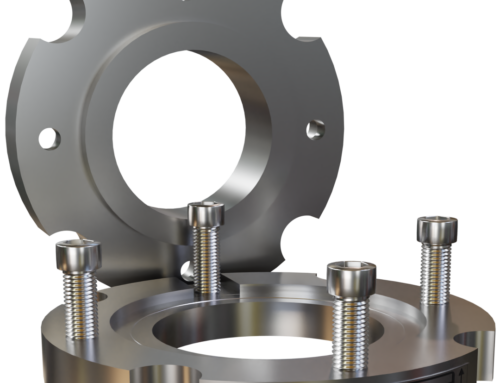

- The STD is designed with a 30° angular seat, and meant to be installed into holders with a matching seat design, such as the RDI. The STD can be configured with a flat seat, and installed into flat seated holders like the FRDI, or FRDI-P. This changes the model name to (F)STD, the (F) indicating a flat seat.

- The STD is a forward acting metal rupture disk. Process pressure is applied to the concave side of the rupture disk. Increasing process pressure stretches the rupture disk until the metal yields and tears open along the weakest areas of the disk.

- The STD, like all for forward acting metal rupture disks, does best in static pressure applications. The STD handles pressure cyclic services fairly well, but reverse acting metal rupture disks are typically recommended, to ensure the tag stays attached to the disk for services with oscillating pressures.

- The STD is offered at lower set pressures with a stiffening ring, to better keep the tag of the rupture disk attached. This configuration is called the RSTD, the R indicating a stiffening ring on the outlet side of the rupture disc.

- The STD is offered with a PFA liner or shield on the inlet side of the rupture disk, to enhance corrosion protection, or to enable better sealing of high pressure, thick STD disks within the holder. This configuration is called the STDL, the L indicating a Teflon liner on the inlet or wetted side of the rupture disc. You can also specify a Teflon liner on both sides of the disc, creating an LSTDL configuration.

- The STD is designed, manufactured, and certified to ASME BPVC Section XIII requirements.

- The STD is designed to pair with the RDI insert holder, as well as Union Type holders, TDH threaded disc holders, and Autoclave assemblies. In its flat seat configuration, the (F)STD is designed to pair with FRDI insert holders, as well as FRDI-P pretorqued insert holders.

- The MNFA for a 0.25″ STD is 0.049 square inches

- The MNFA for a 0.5″ STD is 0.19 square inches

- The MNFA for a 0.75″ STD is 0.44 square inches

- The MNFA for a 1″ STD is 0.6 square inches

- The MNFA for a 1.5″ STD is 1.48 square inches

- The MNFA for a 2″ STD is 2.85 square inches

- The MNFA for a 3″ STD is 5.41 square inches

- The MNFA for a 4″ STD is 10.3 square inches

- The MNFA for a 5″ STD is 22.3 square inches

- The MNFA for a 6″ STD is 45.6 square inches

- The MNFA for a 10″ STD is 72.7 square inches

- The MNFA for a 12″ STD is 101 square inches

- The MNFA for a 14″ STD is 135 square inches

- The MNFA for a 16″ STD is 176 square inches

- The MNFA for a 18″ STD is 230 square inches

- The MNFA for a 20″ STD is 279 square inches

- The MNFA for a 24″ STD is 415 square inches

- For a 0.25” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 220 psig up to a maximum burst pressure of 90,000 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 0.5” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 90 psig up to a maximum burst pressure of 35,000 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 0.75” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 55 psig up to a maximum burst pressure of 30,000 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 1” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 40 psig up to a maximum burst pressure of 3700 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 1.5” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 26 psig up to a maximum burst pressure of 2200 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 2” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 16 psig up to a maximum burst pressure of 2200 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 3” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 12 psig up to a maximum burst pressure of 2200 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 4” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 9 psig up to a maximum burst pressure of 2200 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 6” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 7 psig up to a maximum burst pressure of 3600 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For an 8” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 5 psig up to a maximum burst pressure of 2100 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 10” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 4 psig up to a maximum burst pressure of 1400 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 12” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 4 psig up to a maximum burst pressure of 1000 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 14” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 3 psig up to a maximum burst pressure of 750 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 16” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 3 psig up to a maximum burst pressure of 500 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For an 18” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 3 psig up to a maximum burst pressure of 475 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 20” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 2 psig up to a maximum burst pressure of 450 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- The STD is not currently offered in a 22″ line size.

- For a 24” STD, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 2 psig up to a maximum burst pressure of 450 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.